Archive for the ‘UOA’ Category.

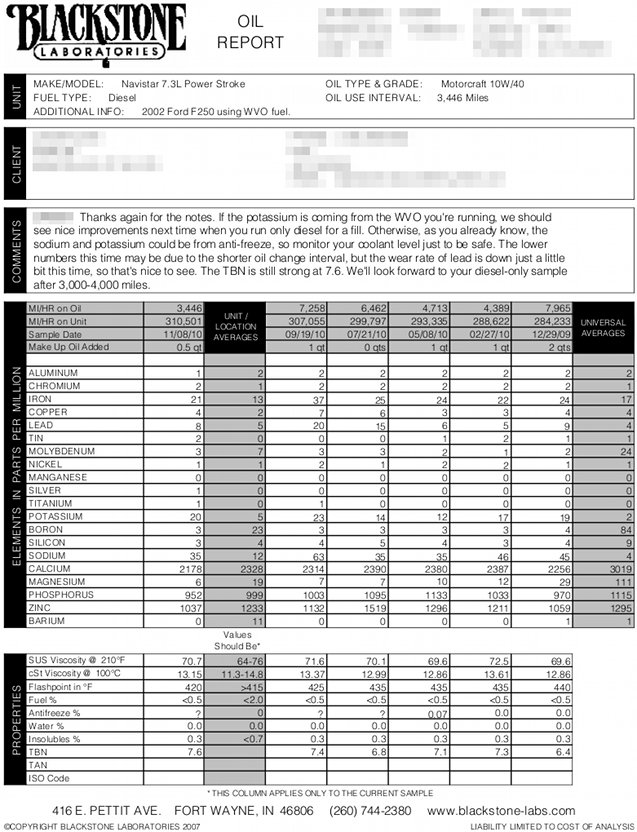

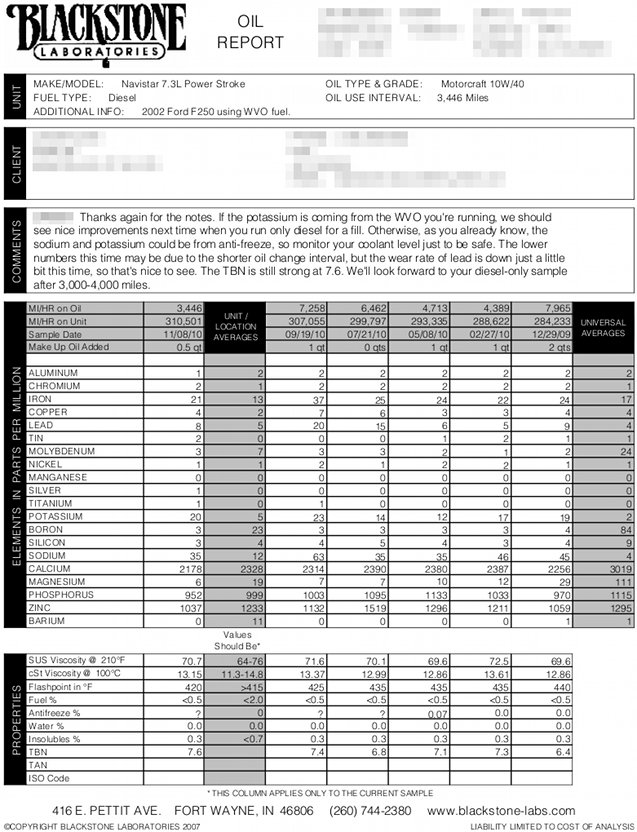

November 8, 2010, 12:00 am

Comments — “Thanks again for the notes. If the potassium is coming from the WVO you’re running, we should see nice improvements next time when you run diesel only for a fill. Otherwise, as you already know, the sodium and potassium could be from anti-freeze, so monitor your coolant level just to be safe. The lower numbers this time may be due to the shorter oil change interval, but the wear rate of lead is down just a little bit this time, so that’s nice to see. The TBN is still strong at 7.6. We’ll look forward to your diesel-only sample after 3,000-4,000 miles.”

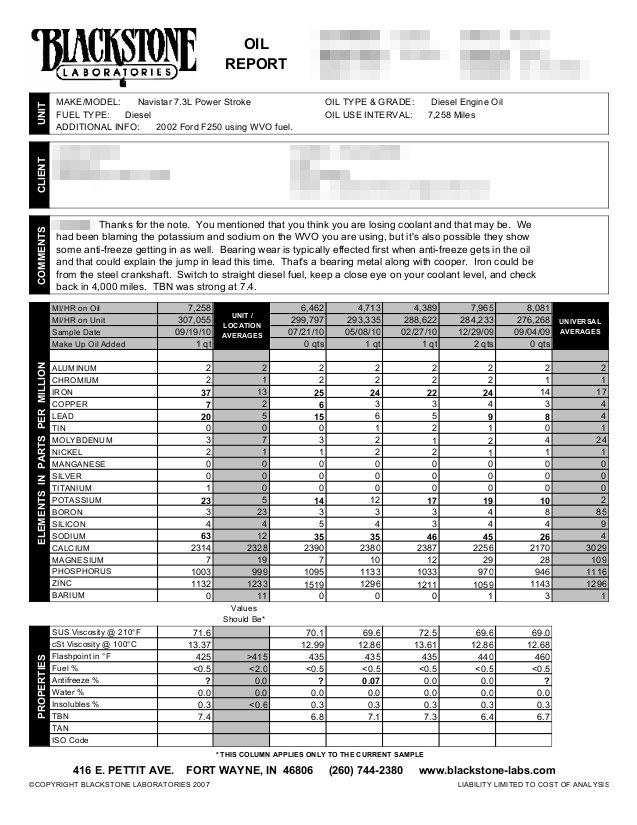

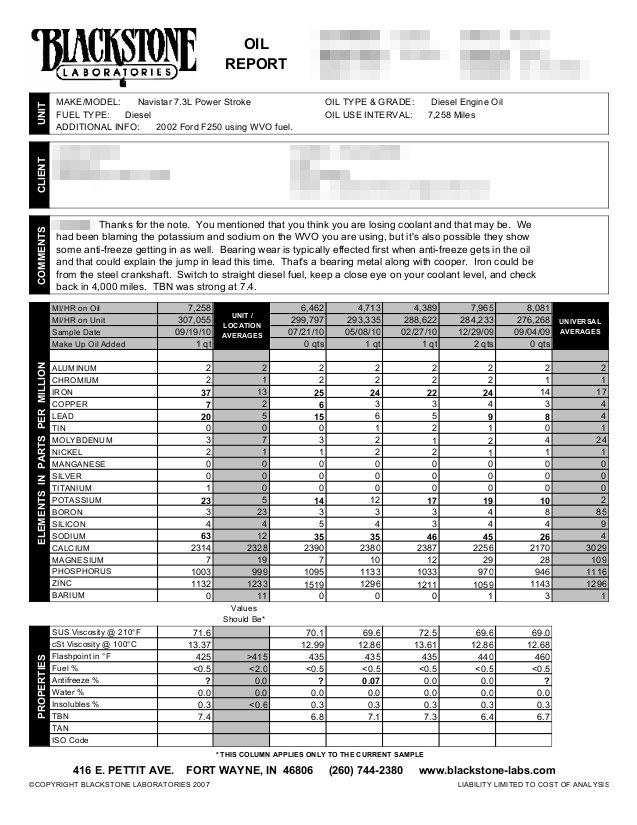

September 19, 2010, 12:00 am

Comments — “Thanks for the note. You mentioned that you think you are losing coolant and that may be. We had been blaming the potassium and sodium on the WVO you are using, but it’s also possible they show some anti-freeze getting in as well. Bearing wear is typically effected first when anti-freeze gets in the oil and that could explain the jump in lead this time. That’s a bearing metal along with cooper. Iron could be from the steel crankshaft. Switch to straight diesel fuel, keep a close eye on your coolant level, and check back in 4,000 miles. TBN was strong at 7.4.”

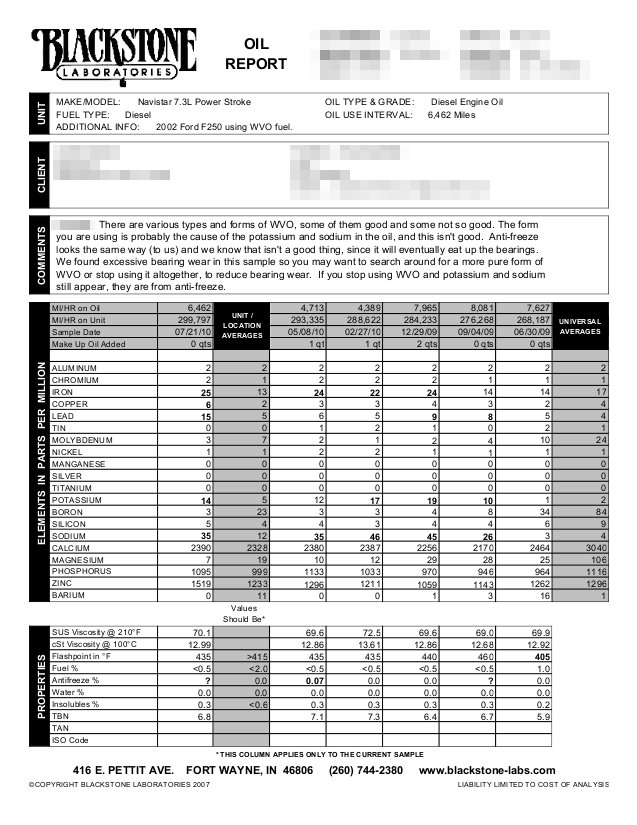

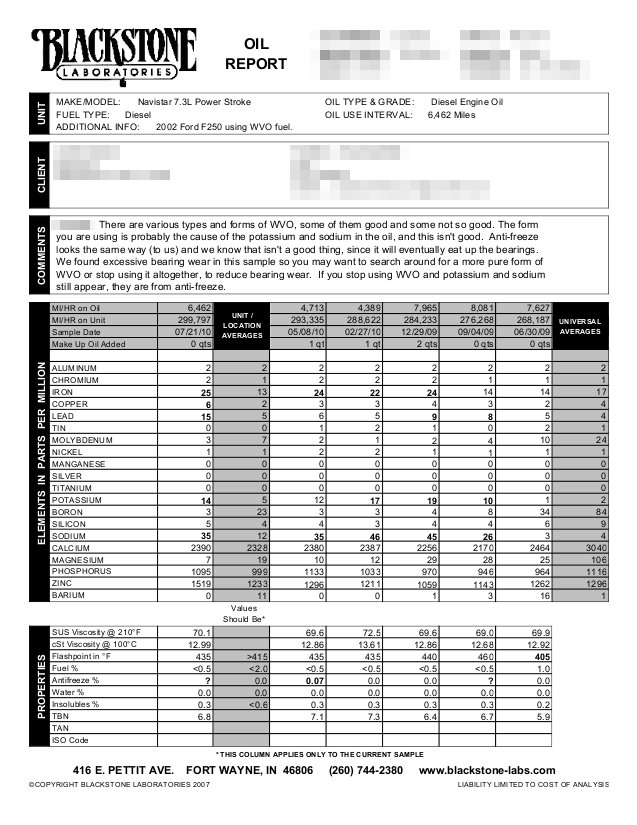

July 21, 2010, 12:00 am

Comments — “There are various types and forms of WVO, some of them good and some not so good. The form you are using is probably the cause of the potassium and sodium in the oil, and this isn’t good. Anti-freeze looks the same way (to us) and we know that isn’t a good thing, since it will eventually eat up the bearings. We found excessive bearing wear in this sample so you may want to search around for a more pure form of WVO or stop using it altogether, to reduce bearing wear. If you stop using WVO and potassium and sodium still appear, they are from anti-freeze.”

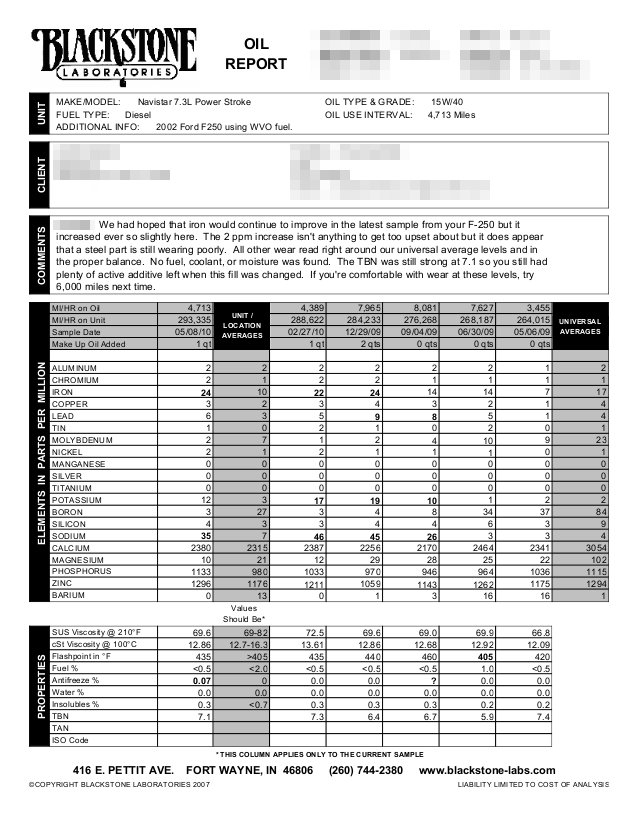

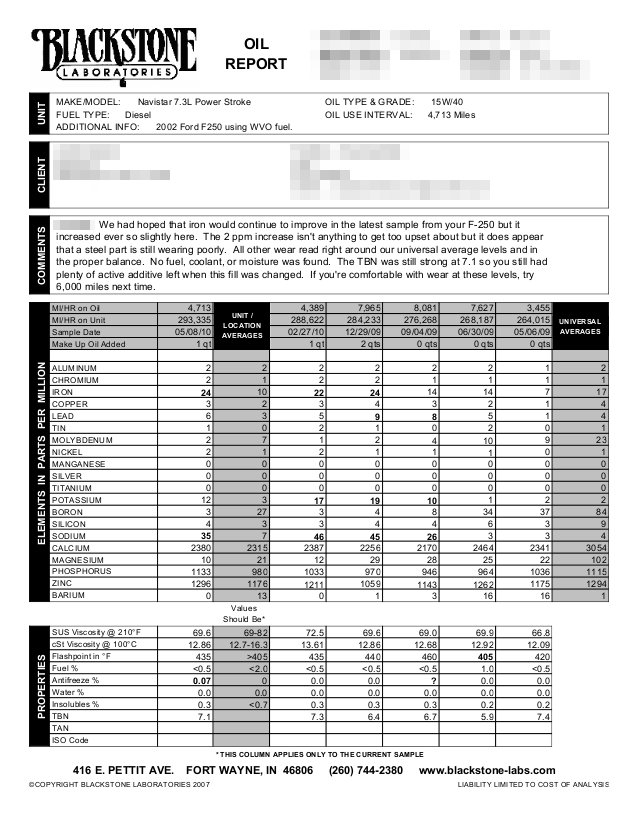

May 8, 2010, 12:00 am

Comments — “We had hoped that iron would continue to improve in the latest sample from your F-250 but it increased ever so slightly here. The 2 ppm increase isn’t anything to get too upset about but it does appear that a steel part is still wearing poorly. All other wear read right around our universal average levels and in the proper balance. No fuel, coolant, or moisture was found. The TBN was still strong at 7.1 so you still had plenty of active additive left when this fill was changed. If you’re comfortable with wear at these levels, try 6,000 miles next time.”

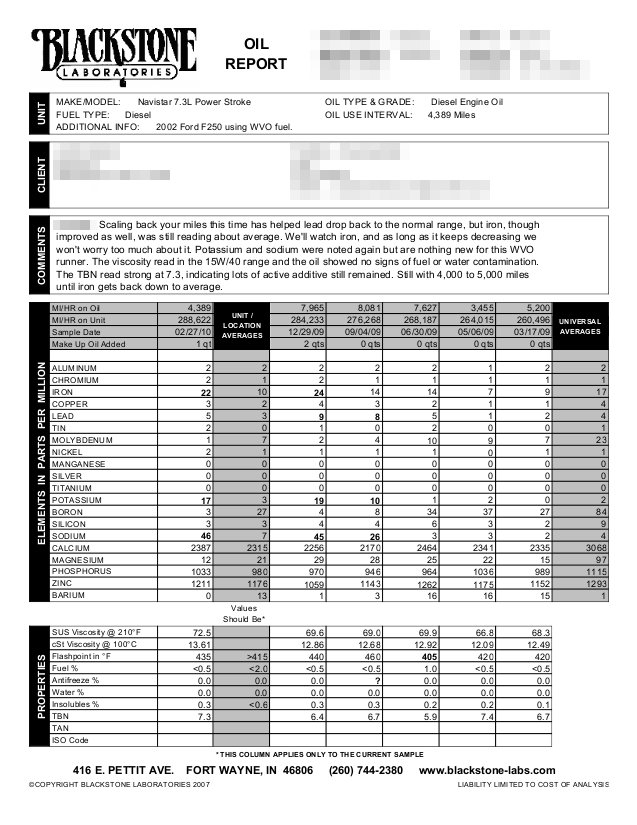

February 27, 2010, 12:00 am

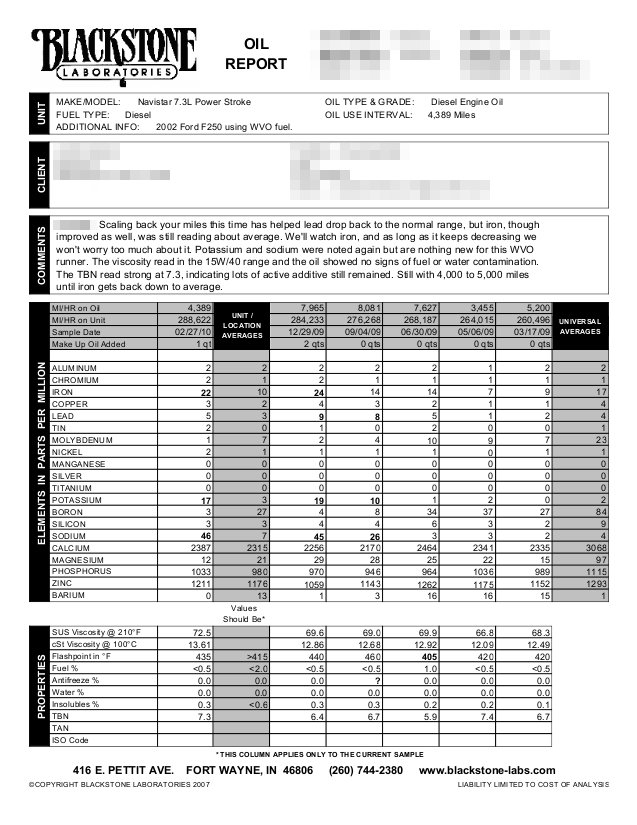

Comment — “Scaling back your miles this time has helped lead drop back to the normal range, but iron, though improved as well, was still reading about average. We’ll watch iron, and as long as it keeps decreasing we won’t worry too much about it. Potassium and sodium were noted again but are nothing new for this WVO runner. The viscosity read in the 15W/40 range and the oil showed no signs of fuel or water contamination. The TBN read strong at 7.3, indicating lots of active additive still remained. Still with 4,000 to 5,000 miles until iron gets back down to average.”

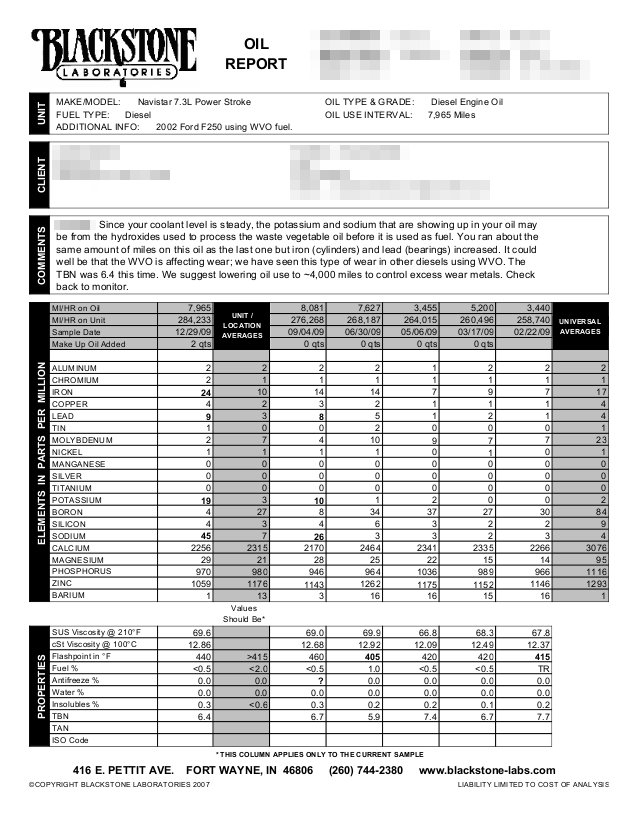

December 29, 2009, 12:00 am

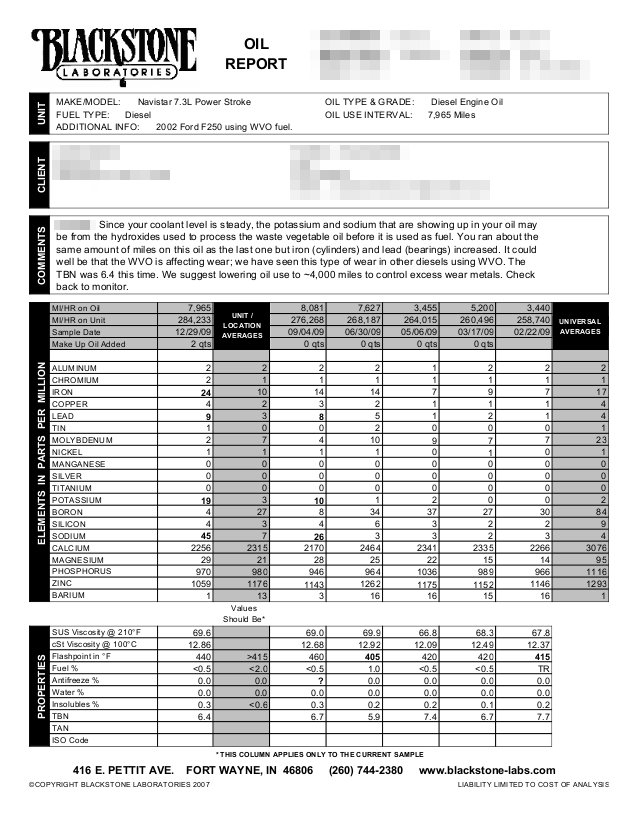

Comments — “Since your coolant level is steady, the potassium and sodium that are showing up in your oil may be from the hydroxides used to process the waste vegetable oil before it is used as fuel. You ran about the same amount of miles on this oil as the last one but iron (cylinders) and lead (bearings) increased. It could well be that the WVO is affecting wear; we have seen this type of wear in other diesels using WVO. The TBN was 6.4 this time. We suggest lowering oil use to ~4,000 miles to control excess wear metals. Check back to monitor.”

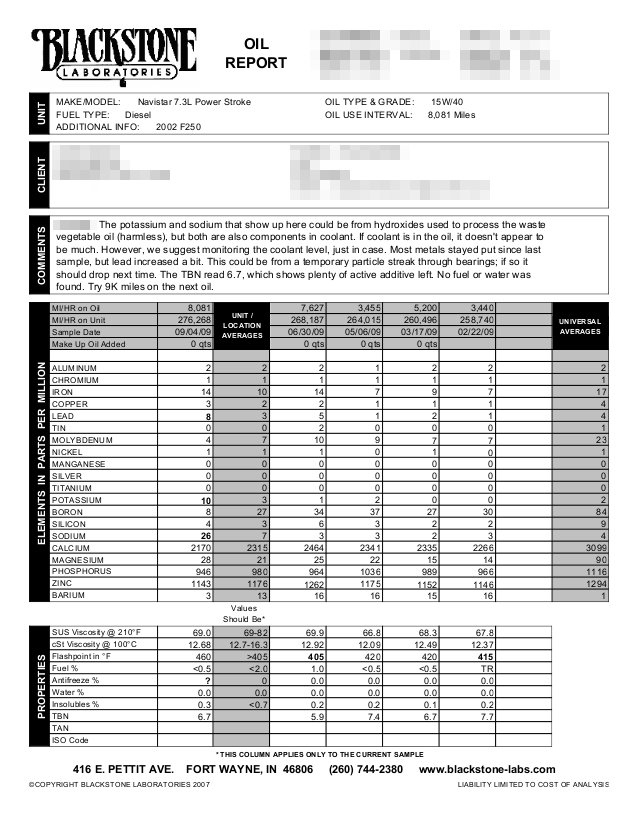

September 4, 2009, 12:00 am

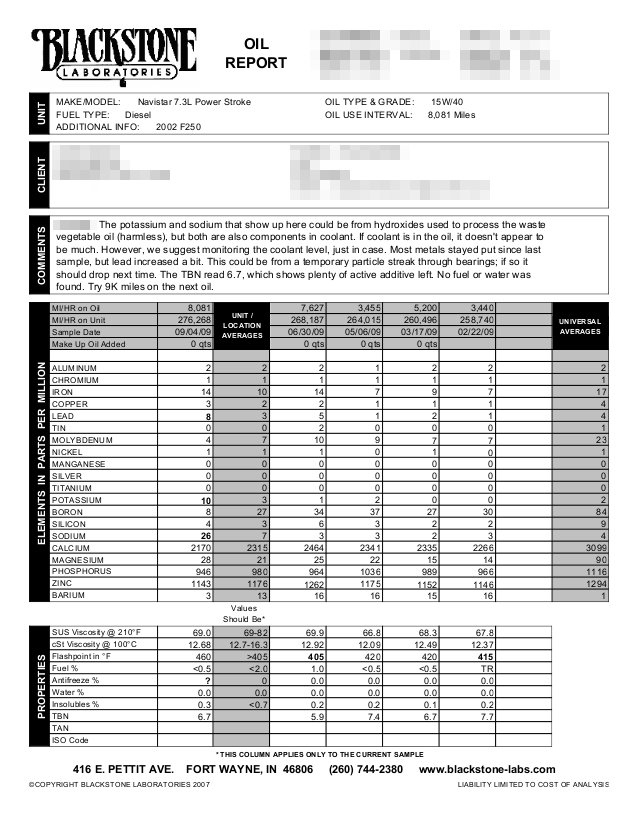

Comments — “The potassium and sodium that show up here could be from hydroxides used to process the waste vegetable oil (harmless), but both are also components in coolant. If coolant is in the oil, it doesn’t appear to be much. However, we suggest monitoring the coolant level, just in case. Most metals stayed put since last sample, but lead increased a bit. This could be from a temporary particle streak through bearings; if so it should drop next time. The TBN read 6.7, which shows plenty of active additive left. No fuel or water was found. Try 9K miles on the next oil.”

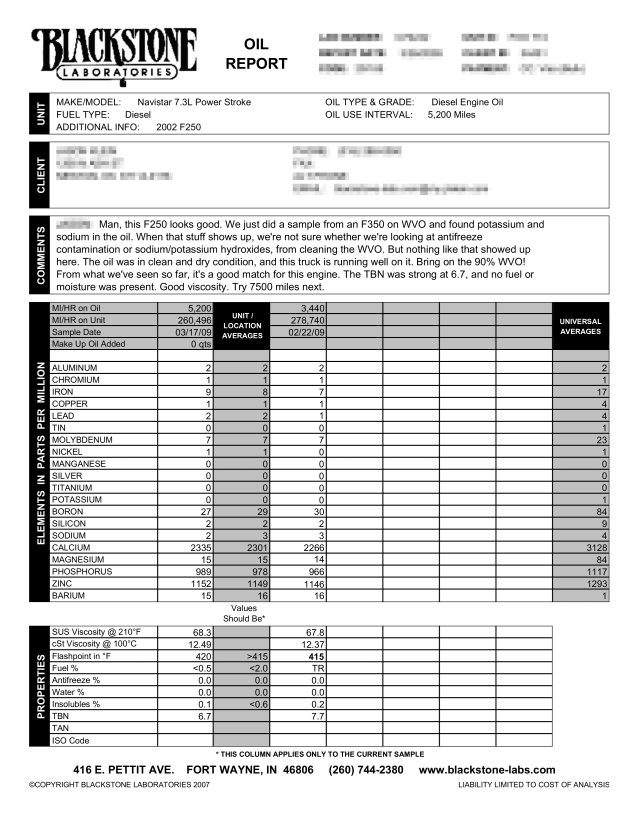

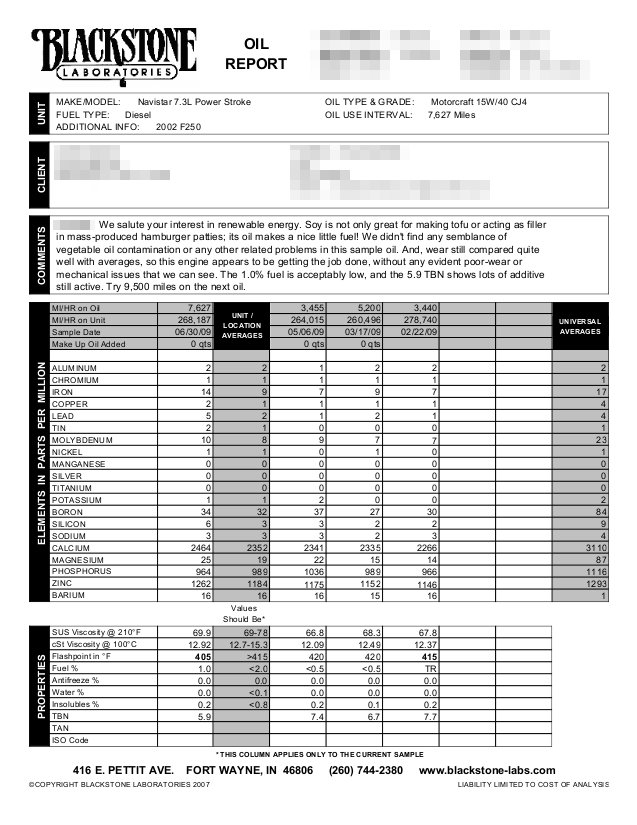

June 30, 2009, 12:00 am

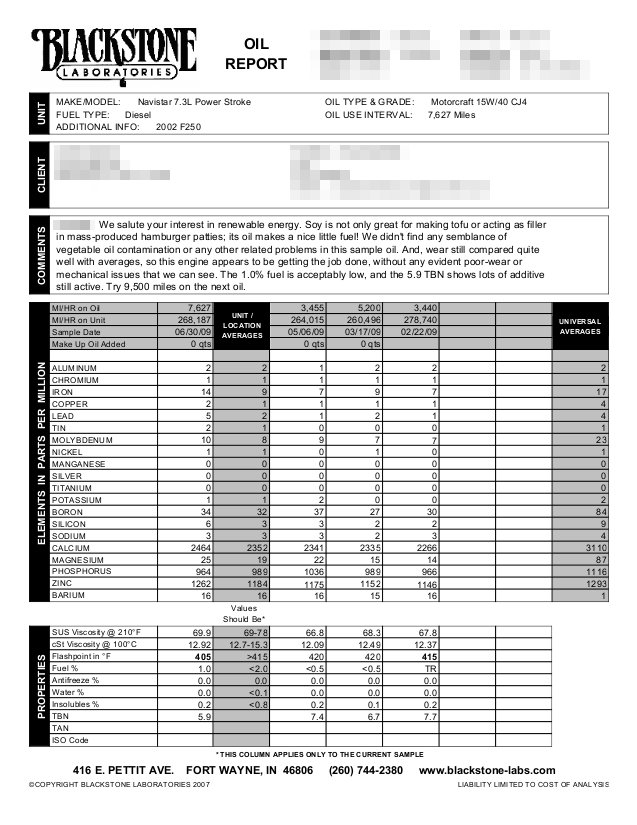

Comments — “We salute your interest in renewable energy. Soy is not only great for making tofu or acting as filler in mass-produced hamburger patties; its oil makes a nice little fuel! We didn’t find any semblance of vegetable oil contamination or any other related problems in this sample oil. And, wear still compared quite well with averages, so this engine appears to be getting the job done, without any evident poor-wear or mechanical issues that we can see. The 1.0% fuel is acceptably low, and the 5.9 TBN shows lots of additive still active. Try 9,500 miles on the next oil.”

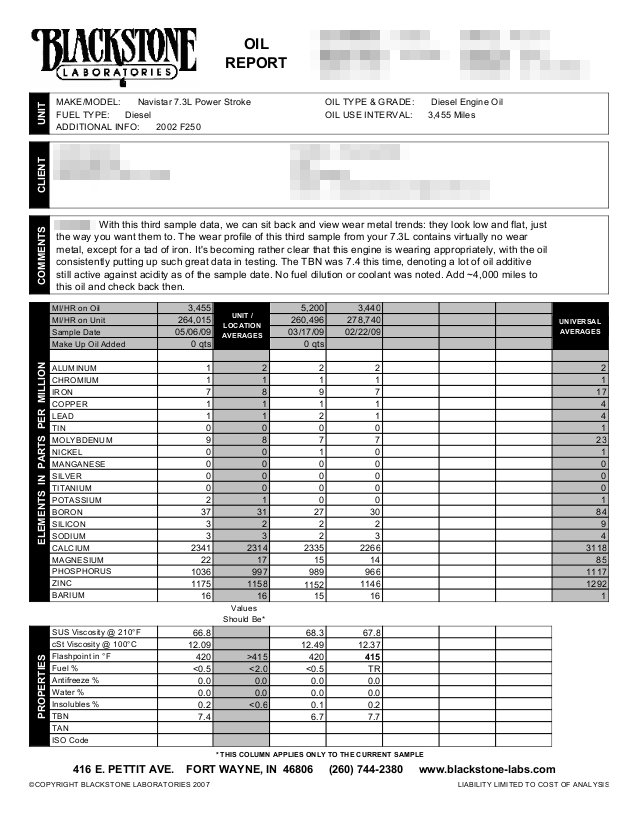

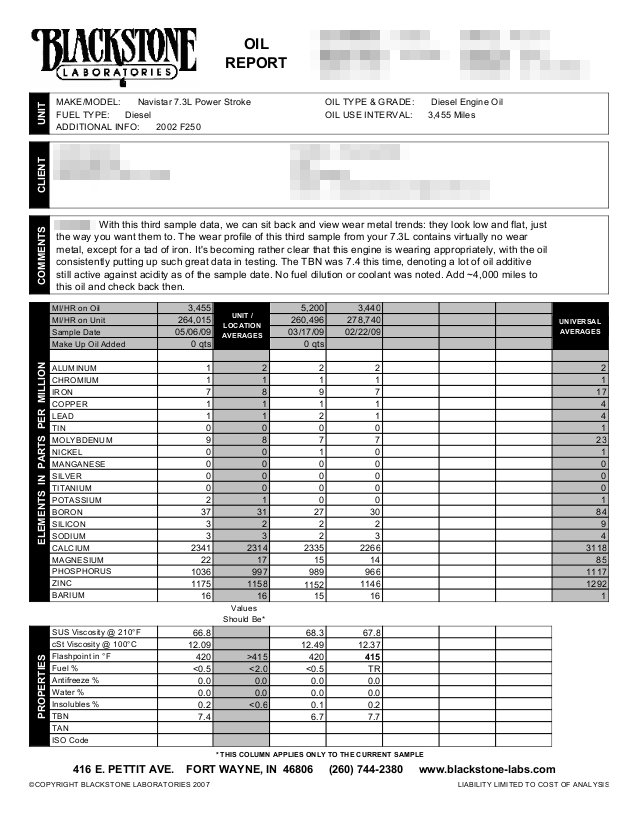

May 6, 2009, 12:00 am

Comments — “With this third sample data, we can sit back and view wear metal trends: they look low and flat, just the way you want them to. The wear profile of this third sample from your 7.3L contains virtually no wear metal, except for a tad of iron. It’s becoming rather clear that this engine is wearing appropriately, with the oil consistently putting up such great data in testing. The TBN was 7.4 this time, denoting a lot of oil additive still active against acidity as of the sample date. No fuel dilution or coolant was noted. Add ~4,000 miles to this oil and check back then.”

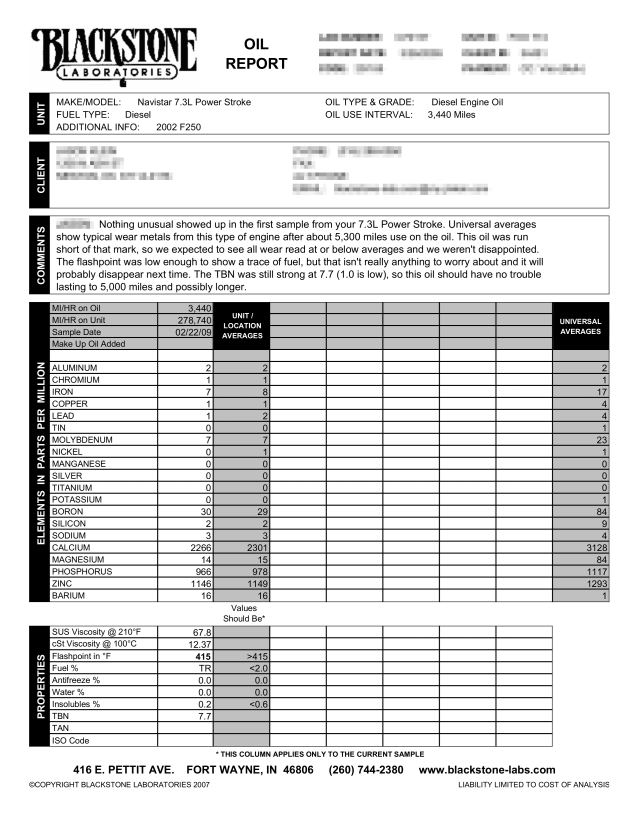

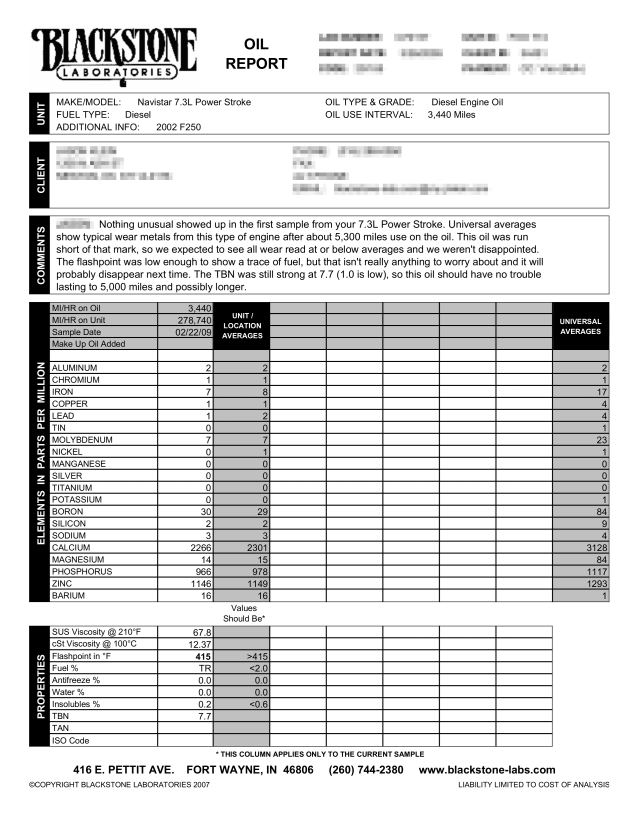

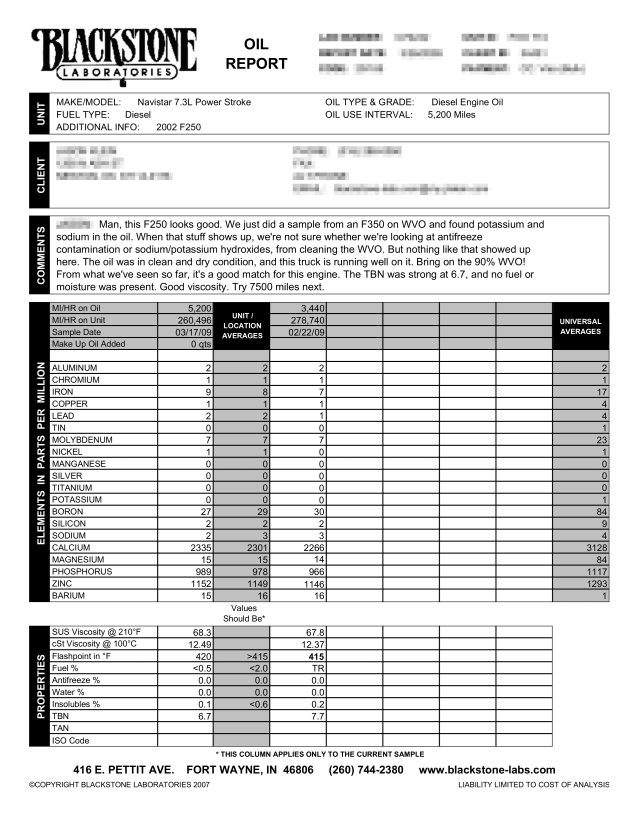

March 26, 2009, 11:08 pm

Dropped both of my first oil samples in the mail about a week ago. Received an email with my first two Used Oil Analysis (UOA) results from Blackstone Labs (http://blackstone-labs.com/). The first UOA reflects 3400 miles on diesel #2 only and was very positive. The second UOA reflects 5200 miles on diesel #2 and an occasional switch to a 50/50 mix of diesel #2 and WVO (canola) and was also very positive. The wear on my F-250 7.3L PSD seems to be below average and the TBN values on my oil seem to be holding up very well. The labs suggested stretching to 7500 miles, but I changed my oil immediately after the 5400 mile sample.

After my last sample and oil change, I continued to gradually increase % WVO in my heated tanks. 50/50, then 40/60, then 25/75, now 10/90. Very unlikely that I will be able to extend usage much past 3000 miles now that I’m running on 10/90 mix of diesel #2 and WVO (canola). Now that I am using a high % WVO in my heated tanks, I plan to send samples again at 3400 miles and 5200 miles so we can compare apples to apples.

Also, I picked up a nice compact 5400rpm bench centrifuge with 15mL tubes from Patricia on Craig’s List for $35 tonight. Hoping to use it to check oil samples for water and particles. She was very interested when I told her how I planned to use the centrifuge and she thought it would work perfectly. She had previously used the centrifuge to test waste water samples while providing consulting to treatment plants. She asked about the possibility of consuming waste fuel from the grease traps at restaurants. I explained that I was simply using fryer oil. Interestingly enough, I just read about the concept of extracting fuel from grease traps at Black Gold Bio Fuels website (http://www.blackgoldbiofuels.com/) in the past few days. Clean grease traps, deliver to processing site, extract fuel (usually 3% of volume), send other 97% to waste-water treatment plant. Good conversation.