Preparing truck bed for WVO tank installation …

I’ve decided to replace the drop-in bed liner with a spray-on bed liner before we mount the GFS tanks in the bed. This weekend we took inventory of all the items received from Bud and GFS.

I’ve been told that there are no really good local Rhino Liner installers, so opted to go with the local Line-X folks. They took a look at the truck while the drop-in liner was present and gave me a quote. Since they couldn’t take a look at the entire bed because of the drop-in bed liner, they warned that large amounts of rust could drive up the price and said that sanding down the rust and treating the areas with self-etching primer could cut down on costs. We planned to work on the rust this weekend, but were pleasantly surprised that rusting was fairly minimal so we just drilled necessary holes for tank mounting, filter draining, and the fuel/coolant/electrical lines.

Truck bed with the drop-in bed liner.

Truck bed without liner. Tanks are in position. Marking holes to be drilled.

My body shop friend took my drop-in bed liner. Sounds like he will be able to use the liner in his truck. If not, told him they were welcome to use it for anything. I was just glad to see it go to use. If he didn’t need it, I would have listed it on CL. No reason to store it. Better than cutting it up and throwing it in the garbage!

Top view of dual 60 gal Trekker tanks. GFS recommends mounting these with the filters on the driver’s side, but what do they know. It’s not like they’ve been doing this for 8 years or anything. I want to be able to do all of my filling on the driver’s side. You can see a fuel fill port near the far left edge of each tank, a larger access port (for cleaning, etc?) near the center of each tank, and a custom-built mount for the heat exchangers, fuel pickups, and fuel fill ports (2 per tank), and fuel sending units on each tank. The Racor 1000 filters are mounted on the passenger side.

UPDATE: I later decided that I’m glad all the fill ports are on the driver’s side, but wish we had drilled the mount holes for the tanks maybe one more ridge to the left. The extra few inches would have allowed for easier access to the drain bowls on the bottom of the Racor 1000 heated filters. I can blindly drain samples into containers to check for water now, but It’d be nice to be able to visually check the front filter, though that one is the least likely to accumulate water since everything runs through the rear/dirty tank and filter first.

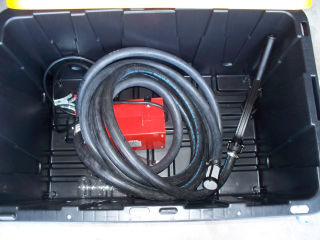

The GFS triple-bypass (3B) hose, manufactured by Parker. UPDATE: The Ford kit barely included enough hose. Would have had extra if we mounted the tanks with the filters on the driver’s side, as per GFS recommendation.

Cross-section view of the GFS triple-bypass (3B) hose. Two 1/2″ Parker coolant hoses, one 3/8″ Parker fuel hose, 4 electrical lines for front tank fuel gauge, rear tank fuel gauge, onboard 3gpm transfer pump (from rear tank, through rear filter, to front tank), and a 10# for the pair of 300W filter heaters. I had to use the truck frame as common ground and had to run an extra line for power to the 7gpm collection pump.

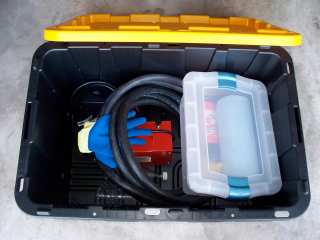

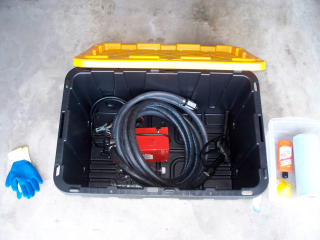

All of the GFS items (including large tanks) were well packed. Everything I received came in 5 boxes: front tank, rear tank, 7gpm pump (not shown), filters and gauge pod, everything else.

Better shot of the box with filters and gauge pod. I expected to receive an a-frame pod, but am glad I received the under dash pod since that will leave room for me to grow into some other gauges (pyro, boost, oil pressure, etc) on my a-frame down the road.

Shot of some of the boxes received in the larger misc box. The only documentation that I originally received was an invoice with an inventory of kit items/boxes, so I could tell that I had received everything marked on the inventory sheets but had no idea how most of it was to be installed. I was pretty intimidated by this at first, but started to sort things out. Things made a LOT more sense after Bud provided a copy of the GFS Ford Kit installation instructions. Glad I asked him about instructions!

Another shot of misc hardware that came with the kit.

UPDATE: In the end, we had to buy a little extra fuel hose and a few different fittings since we mounted the tanks opposite what GFS expects. I guess they wanted us to use the 1/2″ coolant hose with the 1/2″ fuel connectors, but I sprung for a few feet of 1/2″ fuel hose. It seems GFS usually mounts the 3gpm pump to the out port on the Racor 1000. That wasn’t going to work with our configuration, and seemed like a bad idea anyway. We made a bracket so that we could mount the pump on the tanks between the filters. We also ended up NOT using most of their electrical connectors. In some cases we used solder and heat shrink tubing, in other cases we used our own (better) connectors and applied a drop of solder after crimping each connection. We also mounted a 6-fuse block under the hood rather than using their in-line fuse holders. More on this later, when I have time to describe some of the other customizations I came up with to make things more user friendly.